Latest News

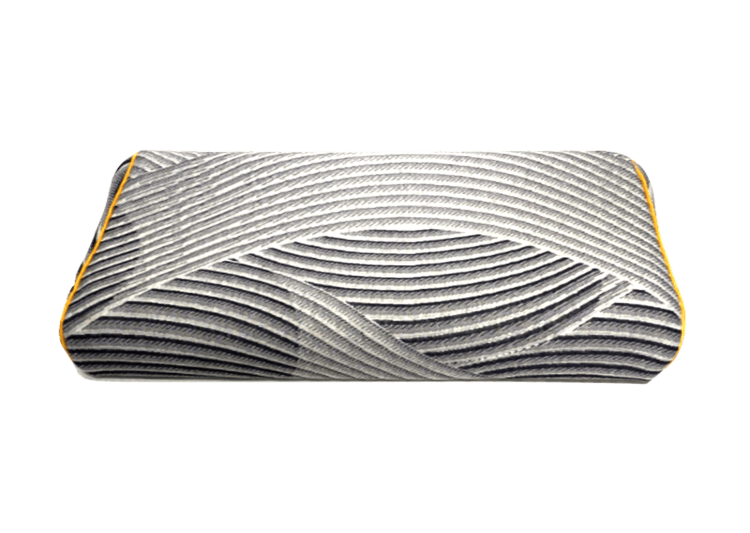

Basic knowledge of printed coarse needle down fabric

Nov 27,2023Printed thick needle-down fabric is one of the process methods for weaving and dyeing fabrics. Since paint is different from dyes, it has no direct effect on fibers. Can not be combined with fiber, it is only an insoluble colored powder, mostly organic compounds, but also inorgan...

Read More >

English

English русский

русский Español

Español 中文简体

中文简体